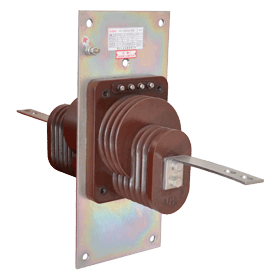

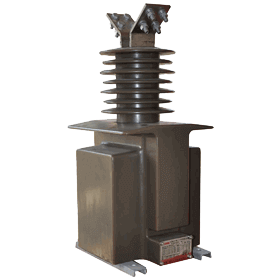

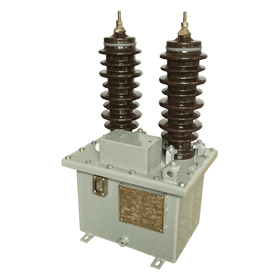

3.3-13.8 kV

Outdoor Current Transformer

Product parameters:

· Outdoor epoxy resin current transformer

· Single phase

· Rated voltage: 3.3kV, 6kV, 10kV, 11kV, 12.5kV, 13.8kV

· Metering class for CT: 0.2S, 0.2, 0.3, 0.5, 0.5S, 0.6

· Standard: IEC, ANSI, GB

· Type name: LZZW-10, LZZBW-11, LZZW-13.8

General

This outdoor dry type current transformer is used in 3.3kV, 6kV, 10kV, 11kV, 12.5kV and 13.8kV power system, for measuring and protection.

It has been used in outdoor pole mounted and transmission line.

The current transformer is made from high quality ultraviolet-proof epoxy resin, amorphous alloy core for metering and high quality CRGO core for protection, primary and secondary use pure electrolytic copper, both winding and core have shielding processing.

Standard

All UNISUN Electric instrument transformers are in conformity with IEC standards, and recommendations IEC 61869. Transformers in conformity with specific country standards can also be supplied. (IEEE C57.13, NBR6855).

Specification data sheet

| Rated primary current(A) | Accuracy classes combination | Accuracy class and output (VA) | Short-time thermal current(kA/1s) | Rated dynamic current(kA) | ||||||

| 0.2s | 0.2 | 0.5s | 0.5 | 10P10 | 10P15 | 10P20 | ||||

| 5 | 0.2S/10P10 0.2S/10P15 0.2S/10P20 0.2/10P10 0.2/10P15 0.2/10P20 0.5/10P10 0.5/10P15 0.5/10P20 0.2S/0.2/10P10 0.2S/0.2/10P20 | 10 | 10 | 10 | 10 | 15 | 15 | 15 | 0.5 | 12.5 |

| 10 | 1 | 2.5 | ||||||||

| 15 | 1.5 | 3.75 | ||||||||

| 20 | 2 | 5 | ||||||||

| 25 | 2.5 | 6.25 | ||||||||

| 30 | 3 | 7.5 | ||||||||

| 40 | 4 | 10 | ||||||||

| 50 | 5 | 12.5 | ||||||||

| 75 | 7.5 | 18.75 | ||||||||

| 100 | 10 | 10 | 10 | 10 | 15 | 15 | 15 | 10 | 25 | |

| 150 | 15 | 37.5 | ||||||||

| 200 | 20 | 50 | ||||||||

| 30o | 30 | 75 | ||||||||

| 400 | 40 | 100 | ||||||||

| 500 | 50 | 75 | ||||||||

| 600 | 15 | 15 | 15 | 15 | 20 | 20 | 20 | 60 | 150 | |

| 800 | 80 | 200 | ||||||||

| 1000 | 15 | 20 | 15 | 30 | 30 | 30 | 20 | 80 | 200 | |

| 1200 | 80 | 200 | ||||||||

| 1500 | 80 | 200 | ||||||||

| 2000 | 80 | 200 | ||||||||

- Products can be customized by customer requirements, above data is standard data, customized data please contact us.

Overall dimension

- Products can be customized by customer requirements, above dimension may change, correct dimension please contact us.

Waiting for your enquiry!

To Learn More info about Us!

Why Buy From Us

Professional Quality Guarantee

Easy and Affordable Payments

Best Product Guarantee

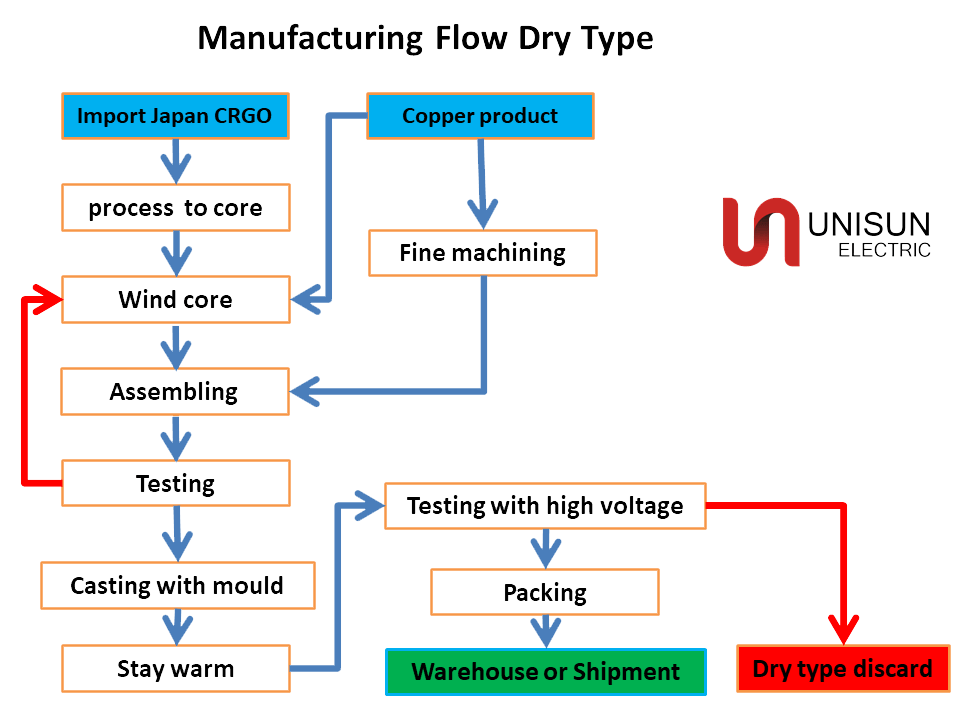

Our Production

The products are designed in strict accordance with IEC or ANSI standards, and the manufacturing steps meet the technological requirements

Primary winding

High electrolytic copper is used as primary winding, silver base welding material is used at the welding place, and semiconductor shielded paper is wrapped to ensure that the partial discharge tseting data is qualified.

Secondary winding

Large capacity design secondary winding, automatic winding, high insulation and high purity enameled wire, to ensure wide capacity output under standard accuracy.

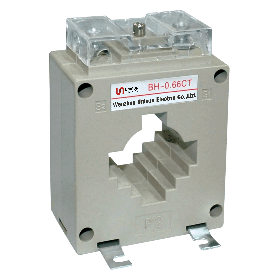

10/11kV Bushing type Current Transformer

33/35kV OUTDOOR CURRENT TRANSFORMER

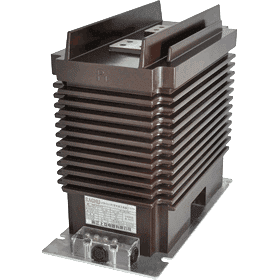

20/24kV Indoor current transformer

Busbar type current transformer

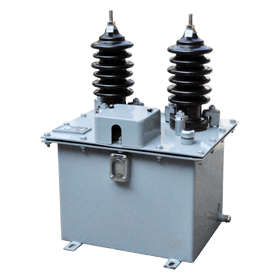

20/24kV Oil type current transformer

Block type CT

Low voltage Outdoor Current transformer

10/11KV OUTDOOR CURRENT TRANSFORMER

33/35kV Indoor current transformer

20/24KV OUTDOOR CURRENT TRANSFORMER

10/11kV Oil type current transformer